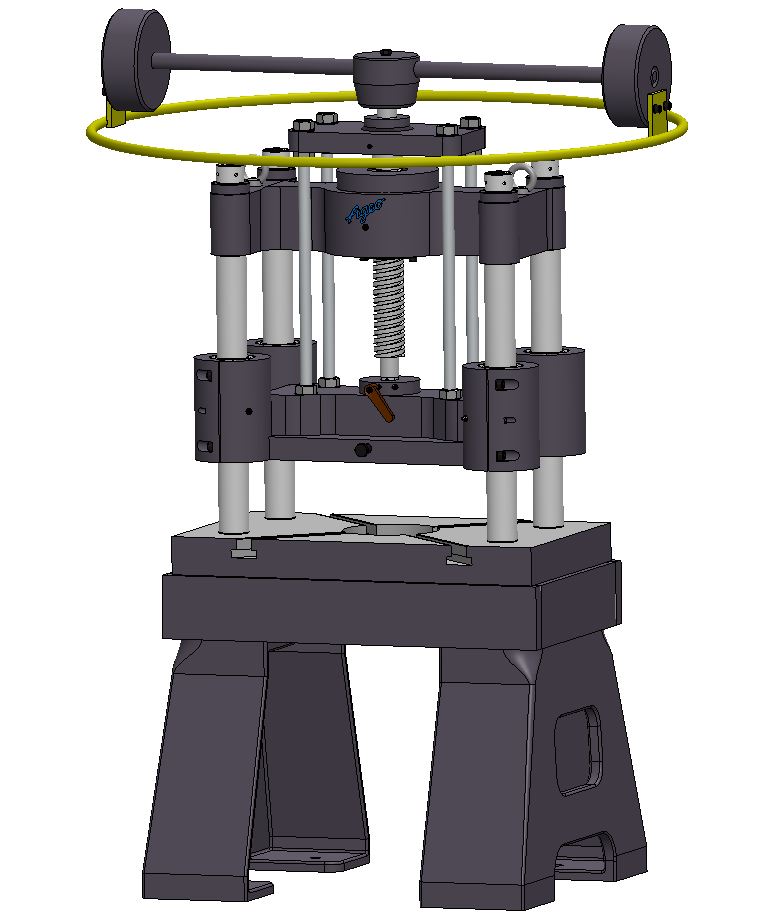

Our screw presses have the following equipment:

• with especially long ram guide,

• great tilting stability through adjustable circular guide bushings,

• are themselves a term for precision, robust design and ergonomic design,

• are the ideal presses for toolmaking.

Screw presses are very versatile and are suitable due to their precise ram guidance for all existing cutting, bending, embossing, stamping and drawing work. Screw presses, due to their accuracy and long-term precision, are indispensable for pressing and spotting in of cutting, stamping, and embossing tools. Their ease of use allows the economical production of small series in materials of all kinds.

The presses can be supplied with enlarged installation and lifting heights for drawing. The circular guide of the press ram can be adjusted within the required limits. The roundness of the guide bushes will pessist. The guide columns are induction hardened and ground; the multiple thread spindles are precision-machined in the thread flanks and made from best steel, the threaded bushings are made of wear-resistant gray cast iron, in case of heavy models they are made of bronze.

Standard versions of AGEO screw presses:

• Base frame

• Locking mechanism for locking the ram when installing tools

• Clamping pivot in ram at the 4-Column presses, with the exception of the model SP 20/500

Special version of AGEO screw presses:

In addition to standard versions we can provide screw presses in different variations. We adapt the presses to your working conditions. A brief inquiry with your specific needs will be sufficient.

Special accessories:

• Cover for through hole in the table top

• Spring pressure device for insertion into the table top

• Forced expulsion in the press ram

• Mounting plate for protecting the table top

• Dirt wiper for protection of the guide columns

The following changes can be performed on all models:

• enlarged or reduced height

• enlarged or reduced stroke of the ram

• differing ram bore for the clamping pivot

• change the diameter of the through hole

• enlarged working area

• T-slots in the working area

+49 (0) 6151 101 50 00

+49 (0) 6151 101 50 00